In addition to an economically and socially focused consideration, a holistic approach to the topic of sustainability particularly includes the responsible use of natural resources and the minimization of pollutant inputs into the environment for PROBAT. This objective is not only in the foreground of our own production processes, but also plays a central role in the development of new technologies. The results are trend-setting product solutions that guarantee a consistently high coffee quality based on environmentally friendly and energy-saving roasting technologies.

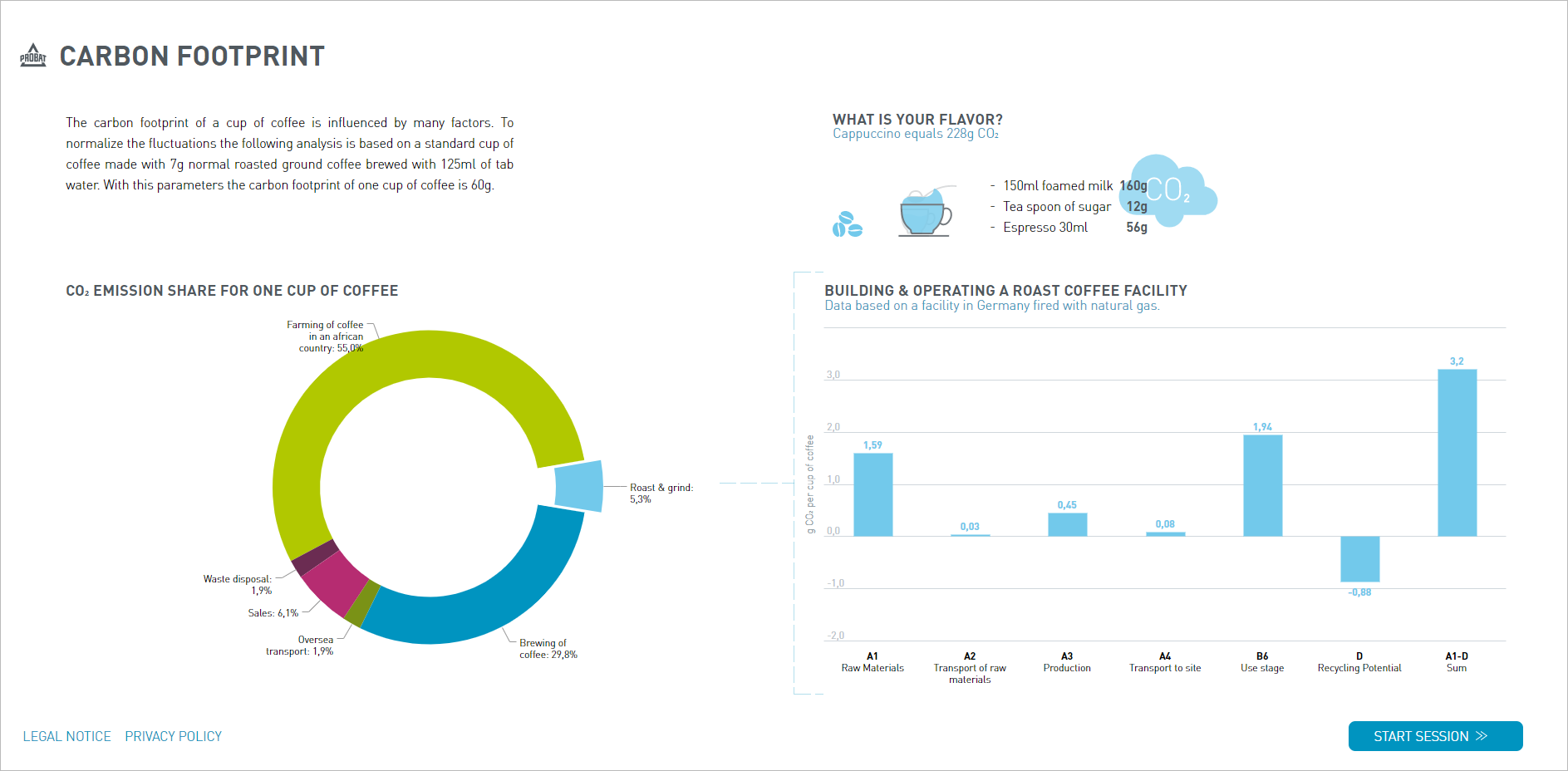

Based on the CO2 footprint of a single cup of coffee, PROBAT has developed a calculation model that enables the analysis of the emissions of a coffee processing plant depending on various parameters. The model illustrates that the negative influence of industrial coffee processing on the climate can be minimized considerably overall, above all by choosing energy-efficient and environmentally friendly roasting technologies by PROBAT.

Furthermore, PROBAT continuously works on the development of new environmentally friendly processes and optimized roasting technologies. For example, the electrically operated PROBAT SAMPLE ROASTER can be operated climate-neutrally using green electricity and is particularly efficient. The green coffee preheating system developed by PROBAT continues to use surplus energy for roasting, which means that less heating energy is required for the roasting process.

The highly efficient PROFORTE exhaust air treatment system reduces emissions to a minimum and enables considerable annual energy savings. PROBAT has further optimized the process so that two or three roasters can now be connected to a single PROFORTE exhaust air treatment system.

The roasting system of the new drum roaster Px 120 was optimized by means of CFD (Computational Fluid Dynamics) analysis to increase coffee quality and energy efficiency. The future-oriented new partial recirculation of the Px 120 reduces the energy consumption by 30% compared to a non-recirculating roasting machine. Equipping all drives of the Px 120 with frequency converters avoids unnecessary energy consumption.